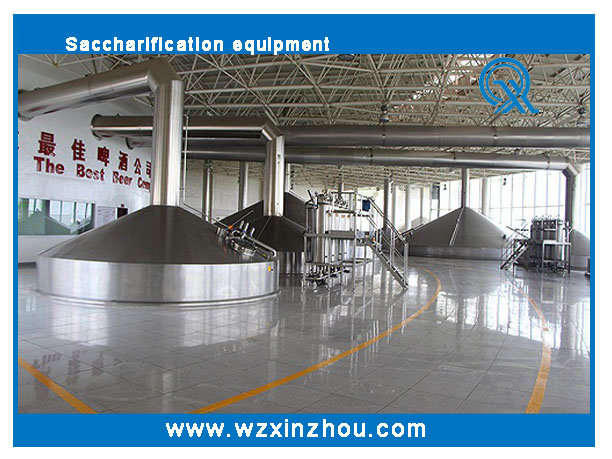

Equipment Specifications:

According to customer's requirements, our Saccharification equipments producing capacity of hot wort juice can be various from 15m³ to 130m³ and the turnkey projects are also available.

Characteristic of the Equipment:

1. Saccharification equipment adopts S30408(SUS304) stainless steel; the surface roughness of the inner vessel will be ≤0.6um; the out surface adopts matt or polished technique that will make it beauty and clean or it can be customized.

2. Mash copper can use micro pressure gelatinization process, efficiently built-in cellular heating jacket, hole type-mixer, compared with trandition equipements, it can save15 minutes to cool the temperature; mash liquefaction more sufficient, improved the usage of the raw material, and save the consumption of steam. The device adopts mechanical seal to make it clean and tidy, prolong the service life of the stirring shaft.

3. Mash tun efficiently built-in cellular heating jacket, mixing hole type, adopts mechanical seal to make the device neat, and prolong the sevice life of the stirring shaft.

4. The tranditional filter tank has several disadvantages, such as centrally located low prepheral speed plow knife, the effects is not so sufficent, low unit load and other weaknesses. Compared to the tranditional model, our new filter tank has made a great improvement, fully and sufficiently use of the filtration area, per square meter of the filter surface has two outflow port, the flow velocity, extract yield is increased to improve the original wort concentration.

5. The latest boiling boilers designed and manufactured canbe classified into three catagories: high efficiency of compulsory boiling; low pressure dynamic boiling; automatic circulative boiling; all of these can effectively reduce the boiling time and save large amout of energy.